Post Fracture Evaluation

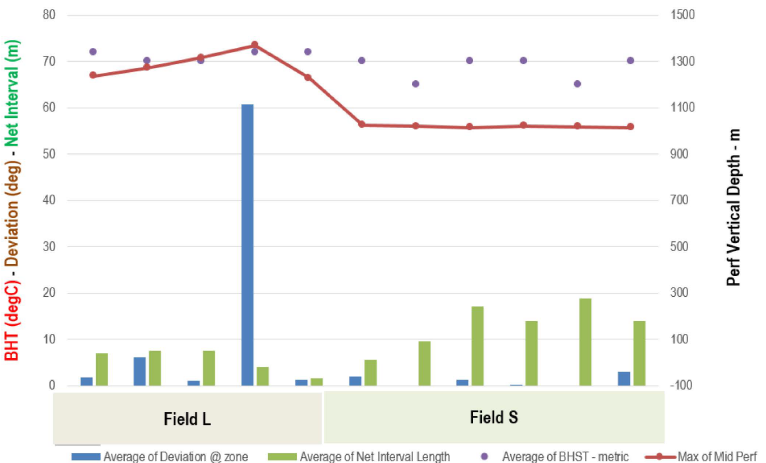

Master databases were collected to include critical information:

- Well & reservoir data

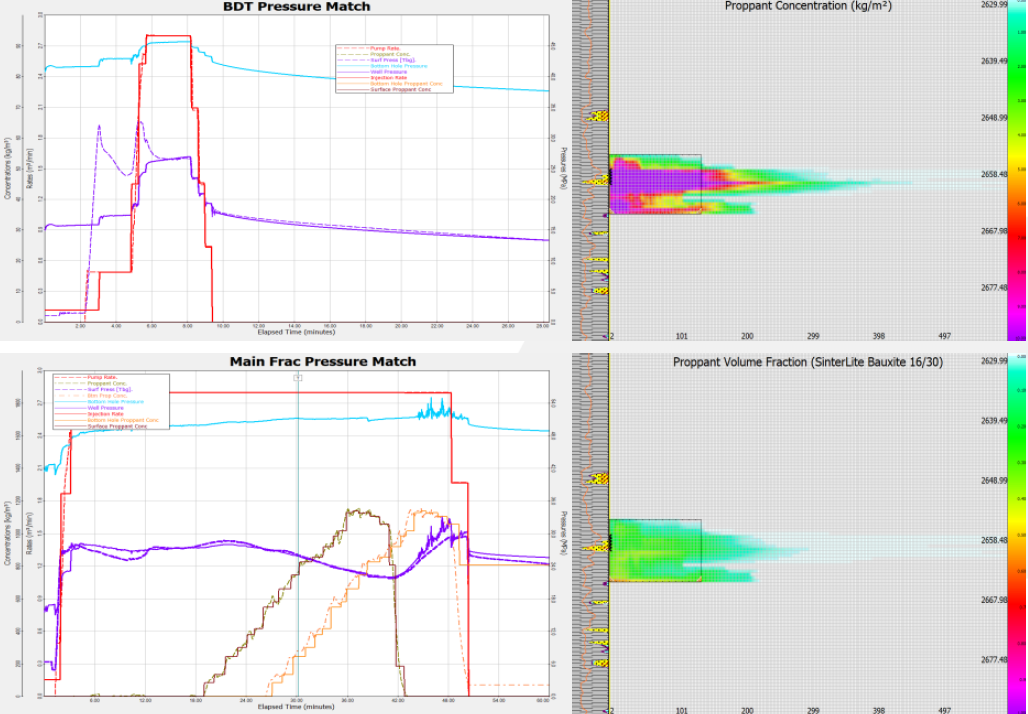

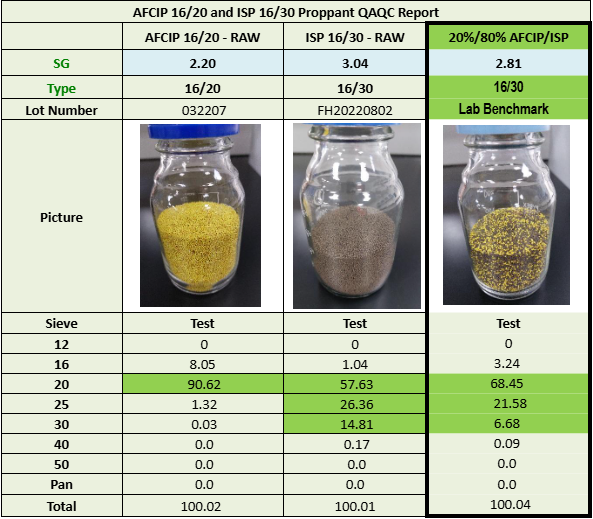

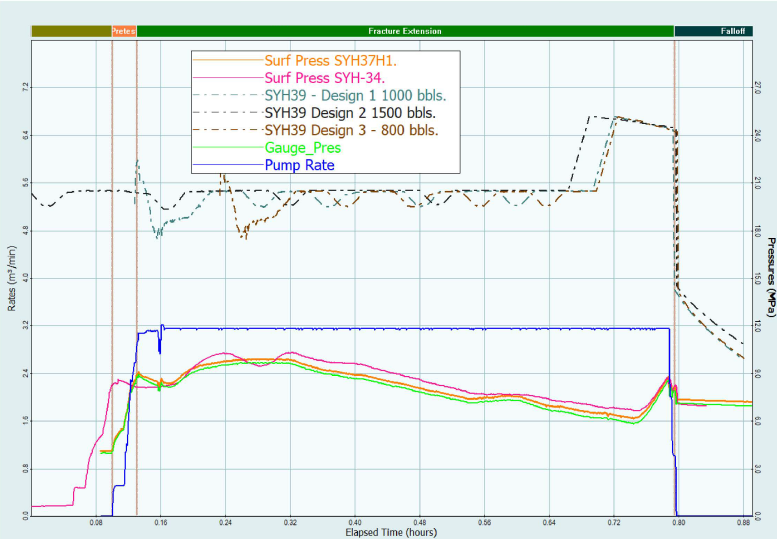

- Design & actual treatment parameter

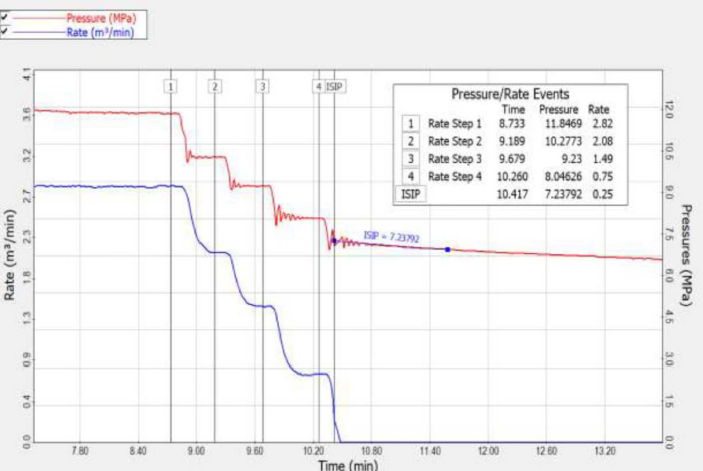

- Pressure, rate data and diagnostics

- Other operational parameter

Following the fracturing campaign:

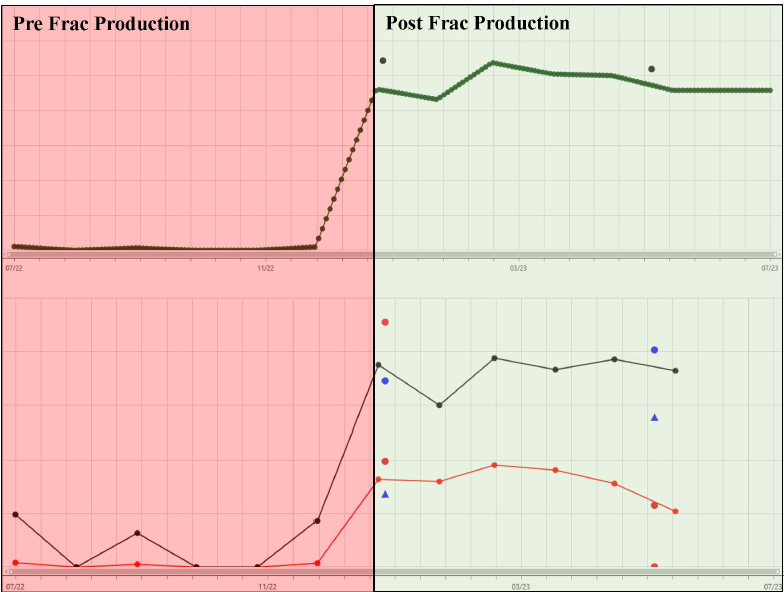

- Substantial improvement in both gross and net oil production (oil production increased by a factor of 20).

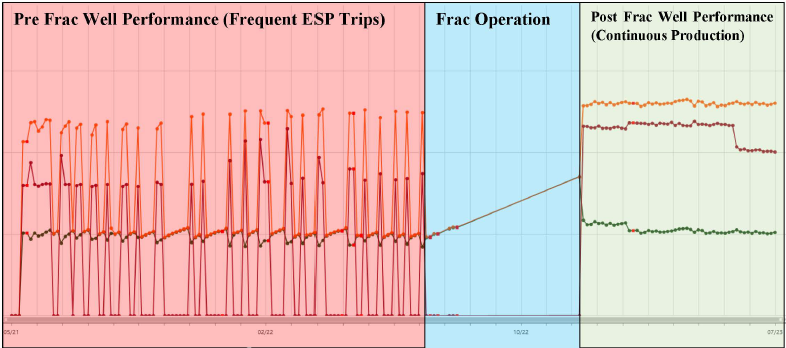

- Productivity was sustained, uptime improved from 25% to 100%.

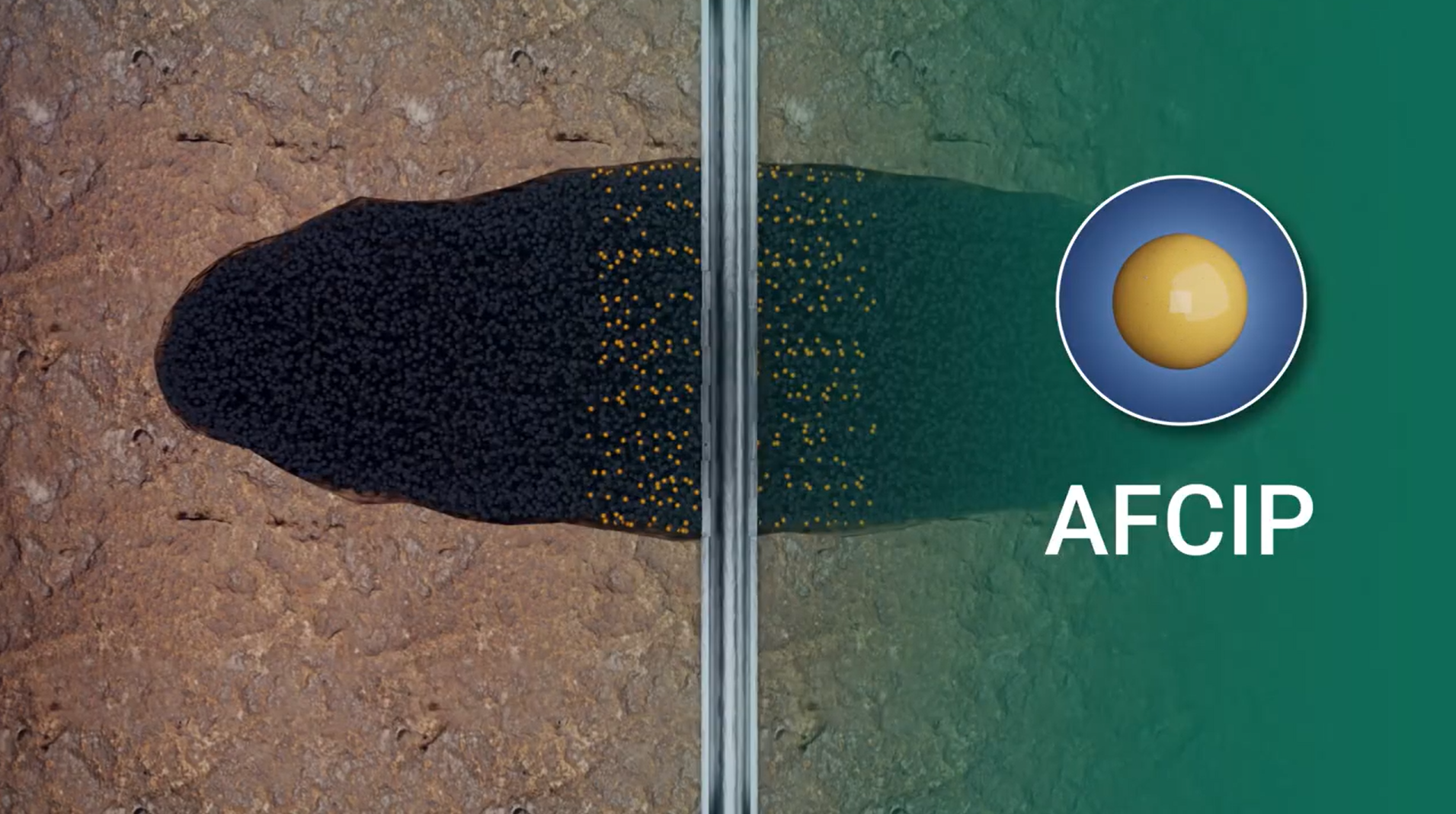

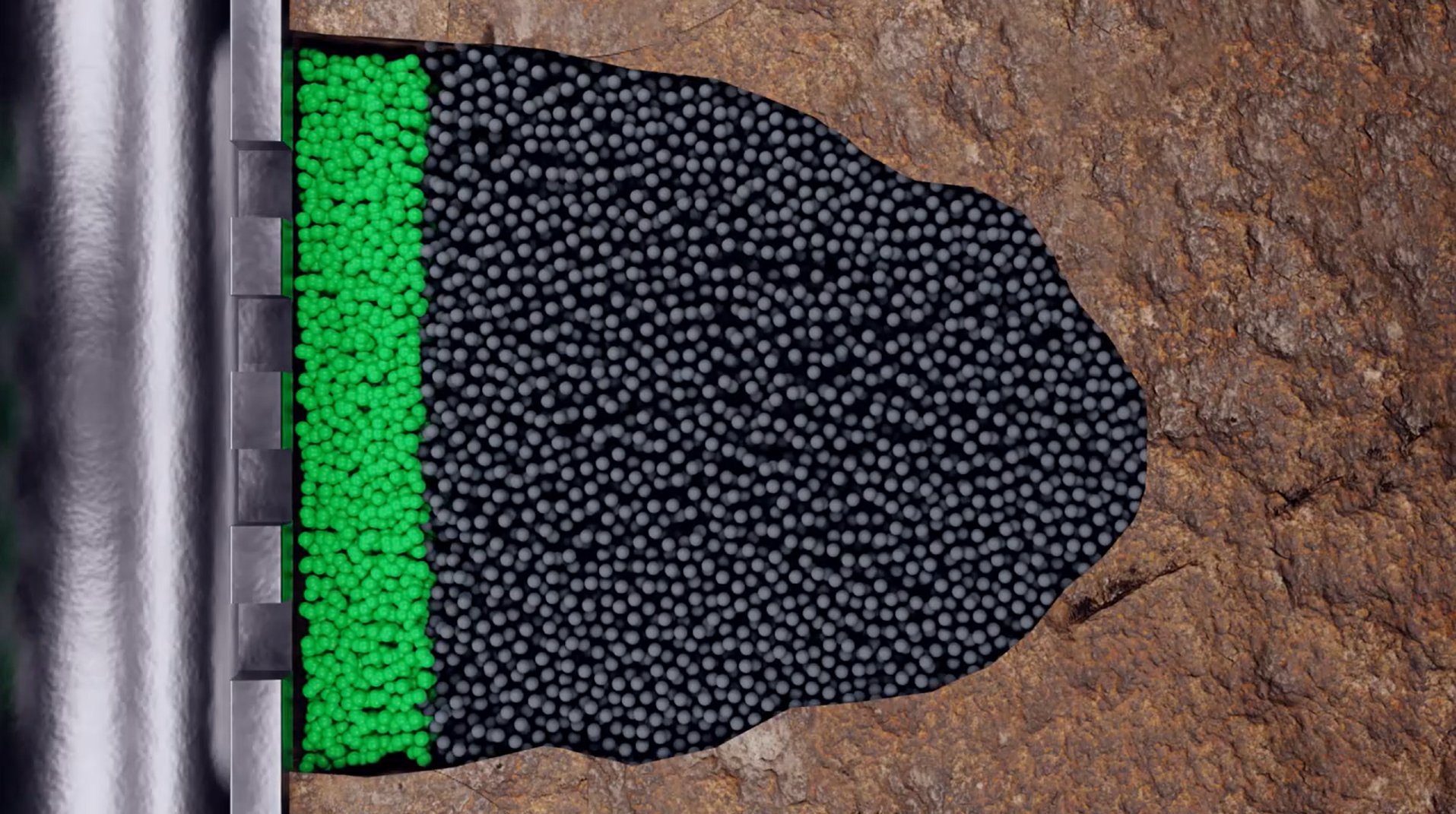

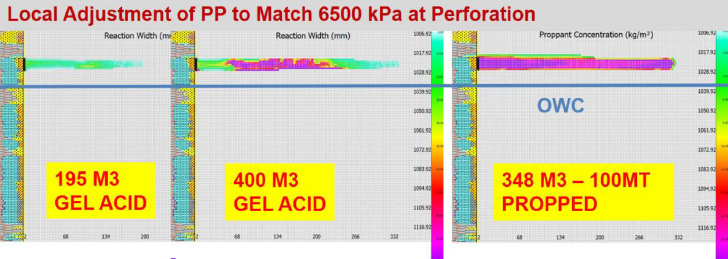

- Propped fracturing method is preferred when applicable, while retarded acid fracturing provide more flexibility for complex pre-existing well completion